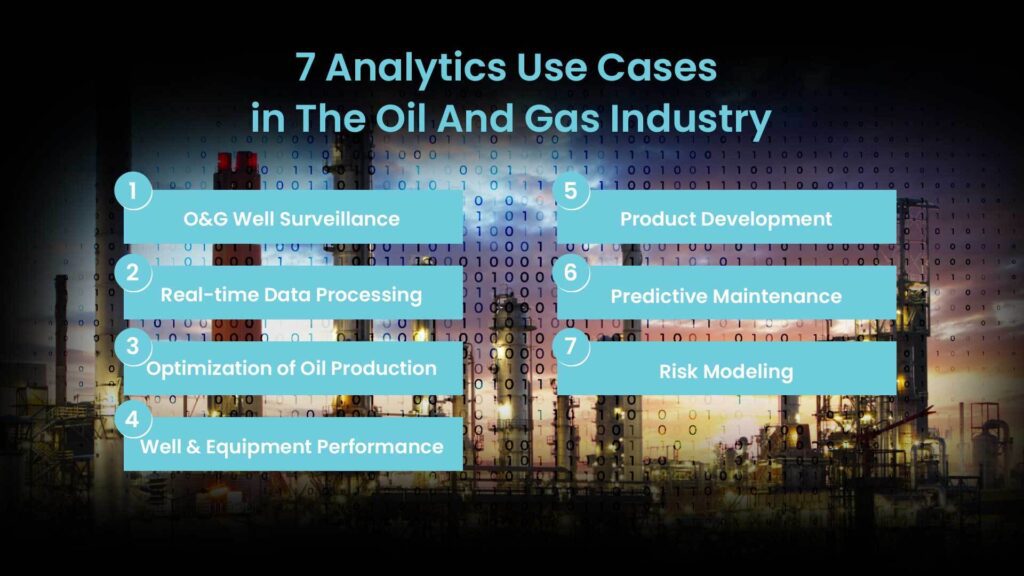

O&G Well Surveillance

Predictive and prescriptive analytics has made good monitoring seamless. Surveillance means effectively tracking the reservoir levels, quality, quantity, and flow station facilities. The real-time infrastructure activity monitoring also enables petroleum industries to control the contamination of unwanted effluents in O&G reservoirs.

Good surveillance assists businesses in drawing more accurate conclusions. Artificial intelligence and machine learning introduced well-activity monitoring IoT devices to collect and forecast data to the system. These integrated digital devices draw insights for business intelligence and development teams to generate oil and gas industry leads.

Real-time Data Processing

The data processing unit is an automatic machine learning model which evaluates the real-time data collected at different phases in the O&G processing system. The processed data is used to draw massive data analysis dashboards and reports for business owners to understand their O&G infrastructure and business future. Data processing is one of the potential use cases in the oil and natural gas industry.

Optimization of Oil Production

Real-time optimization of refineries via the enactment of AI (Artificial Intelligence) and ML (Machine Learning) solutions deployed to the production units. Optimization algorithms, system models, and sensors collaborate with the data assimilation module to evaluate the well and facilities optimization in oil and gas production units.

The data assimilation algorithms deployed to optimize oil production is itself an intelligent system that forecasts production and retunes the internal parameters of refineries, wells, and facilities to get maximum oil and gas production to maximize the business return.

Well & Equipment Performance

The equipment performance is evaluated in terms of how sufficient manufacturing operations are. The well and equipment performance is measured in terms of the percentage of scheduled production time that is fully utilized to maximize the return. Furthermore, equipment technology (Simulators/Sensors), troubleshooting, and monitoring IoT devices are installed to measure the oil and gas reserves potential.

Product Development

The enhancement due to artificial intelligence in oil and gas brings new opportunities for O&G businesses to develop new products for the market. The natural gas extraction and purification process have been 99% accurate, whereas the raw products (additional gasses and oil derivatives) can be used to launch new products for the O&G business.

Process automation through machine learning and fuzzy logic has reinvented the extraction and purification process with 0.1% inaccuracy.

Predictive Maintenance

The gas and oil businesses are risky and full of challenges due to highly volatile materials. The predictive and prescriptive maintenance software tools and strategies assist businesses to grow fearlessly and without losing millions of dollars explicitly on maintenance. The latest artificial intelligence-based predictive maintenance tools are serving the O&G industry in the following ways.

- Real-time Maintenance Triggering

- Instant System Maintenance with AI-Automated Strategies

- Well, Refineries & Production Plants Maintenance

- Prescriptive Insights as Visualization

- Data analytics tools to forecast upcoming system maintenance.

Risk Modeling

Expert systems, machine learning, fuzzy logic, and business intelligence have changed the conventional ways of risk modeling through AI-based systems. These tools autonomously operate and evaluate value at risk, historical simulation, market risk, and extreme value theory.

In addition, these strategies predict the future of the oil and gas sector via real-time data analysis and modeling. Risk modeling helps businesses to pre-plan everything and take action before they affect the business due to any market volatility.

The above-discussed use cases in the oil and gas industry have changed the way this industry operates. Now, let’s overview how artificial intelligence and machine learning make a difference in the O&G sector.

How is AI ML in the Oil and Gas Industry Evolving?

Artificial intelligence and machine learning in the oil and natural gas sector drastically changed everything. It has automated the whole process from upstream to O&G downstream processes. Furthermore, the industrial 4.0 revolution has changed these sectors in the following ways according to the use cases in the oil and gas industry.

- Automatic oil and gas natural reserves detection.

- Monitoring and tracking oil and gas refineries as well as plants.

- Streamline the oil and gas upstream process, including exploration, drilling, and extraction.

- Real-time data collection from upstream, midstream, and downstream operations.

- Innovation for new products according to consumer demands.

- Predictive equipment maintenance in deep-water locations.

- Maintenance forecasting using unstructured sensors & historical data.

Odyssey Analytics as Your Business Partner

Odyssey Analytics aid state-of-the-art time series forecasting services that assists the oil and gas sector in uncountable ways. We service O&G companies to forecast supply and demand under different use cases and conditions. We ensure quality assurance capabilities make the whole system fast and accurate with less investment to check gas, oil, and their derivative’s qualities. Besides the above data analytics use cases in the oil and gas industry. Odyssey Analytics services companies in the following ways.